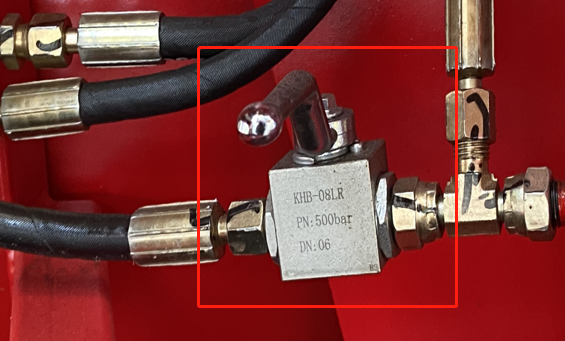

Information Of High Pressure Ball Valve

Working Principle

The high pressure hydraulic ball valve only need to turn 90°from fully open to fully closed.

This design is actually more conducive to remote control.When the ball rotates 90°, the inlet and outlet will fully present a spherical surface ,so it can cut off,distribute and change the flow direction of the medium in the pipeline.

Performance

Simple structure,small size and light weight.

Easy to operate,just turn 90°to open and close

Good Quality ,corrosion resistance, high temperature resistance

The sealing is good , we use German manufacturing , more compact and reliable

Valve And Pipeline Installation Method

Remove the thread protectors at both ends or three ends of the ball valve open the ball valve for simple flushing, and wipe dry

Check the pipeline connecting two holes or three holes clean and dry the magazines in the pipeline before connecting and wipe dry

When the pipe is connected to the ball valve it should be at the same water level or player vertical

After installation, remember to open and close the ball valve several times to prove that the ball valve is working normally.

Precautions

If you don’t use high pressure hydraulic ball valves , please put them in a dry place to prevent the ball valves from getting wet

Before maintenance, remember to disconnect the power or air source

Before disassembly, please ensure that the pressure inside the ball valve and the upstream and downstream pipelines is no longer

If you want to use lubricant to lubricate and prolong the service life of the high-pressure hydraulic ball valve, the grease should also be compatible with the ball valve and parts, such as 221 grease.

If a cleaning agent is used during cleaning, the cleaning agent cannot collide with the high-pressure hydraulic ball valve and internal parts. When the working medium is gas, gasoline (GB484-89) can be used to clean metal parts. Clean non-metallic parts with pure water or alcohol

英语

英语 德语

德语 中文简体

中文简体

-1.jpg?imageView2/2/w/400/h/400/format/jp2/q/75)

3.jpg?imageView2/2/w/400/h/400/format/jp2/q/75)

Home

Home